| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu6240 | |

| AWS A5.7:2007 | ERCuAl-A3 |

|

| BS EN ISO24373:2009 | CuAl11Fe3 |

|

| AWS Chemical Composition: | % | |

| Cu incl.ag | bal. | |

| Zn | 0.10 | |

| Fe | 2.00-4.50 | |

| Si | 0.10 | |

| Al | 10.00-11.50 | |

| Pb | 0.02 | |

| Total others | max 0.50 | |

| Physical properties of materials: | ||

| Density | Kg/m^3 | 7.7 |

| Melting range | ℃ | 1030-1045 |

| Thermal conductivity | W/m.K | 55 |

| Electrical conductivity | S.m/mm^2 | 6.7-7.7 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 16.7 |

| Standard values of the weld metal: | ||

| Elongation | % | 33 |

| Tensile strength | N/mm^2 | 500 |

| Notched bar impact work | J | 96 |

| Brinell hardness | HB 2.5/62.5 | 145 |

| Applications: | ||

| It is used for joining and repair welding of aluminum bronze castings of similar composition,and for depositing bearing surface and wear and corrosion resistant surfaces.Welding in the flat position is perferred.Welding in other positions can be done successfully with pulsed arc welding euipment and welder technique. | ||

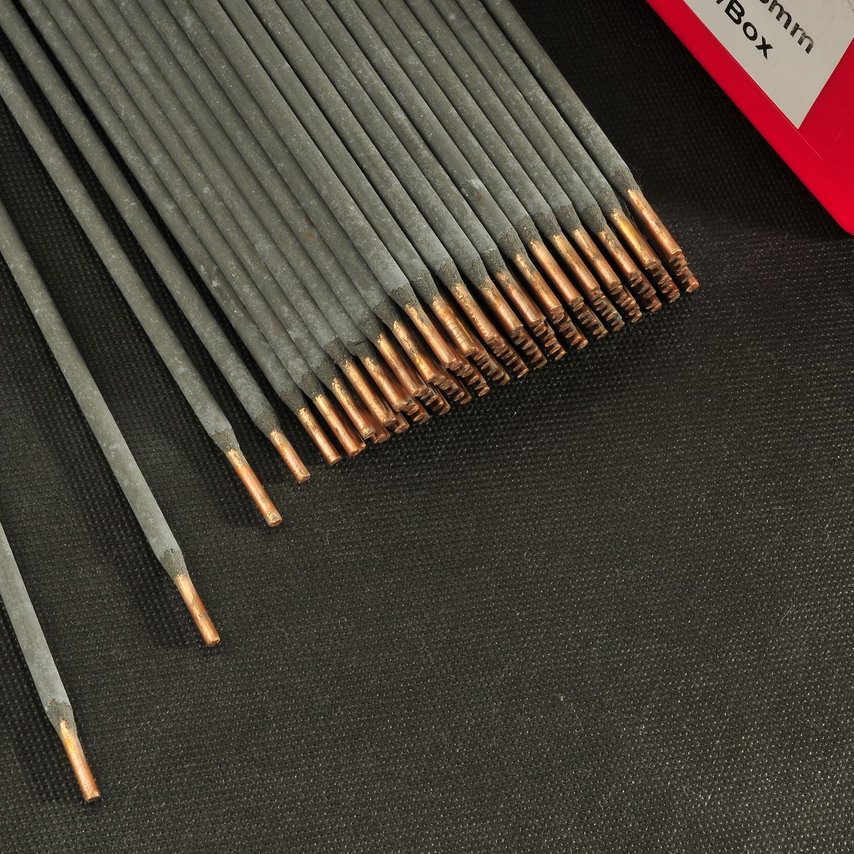

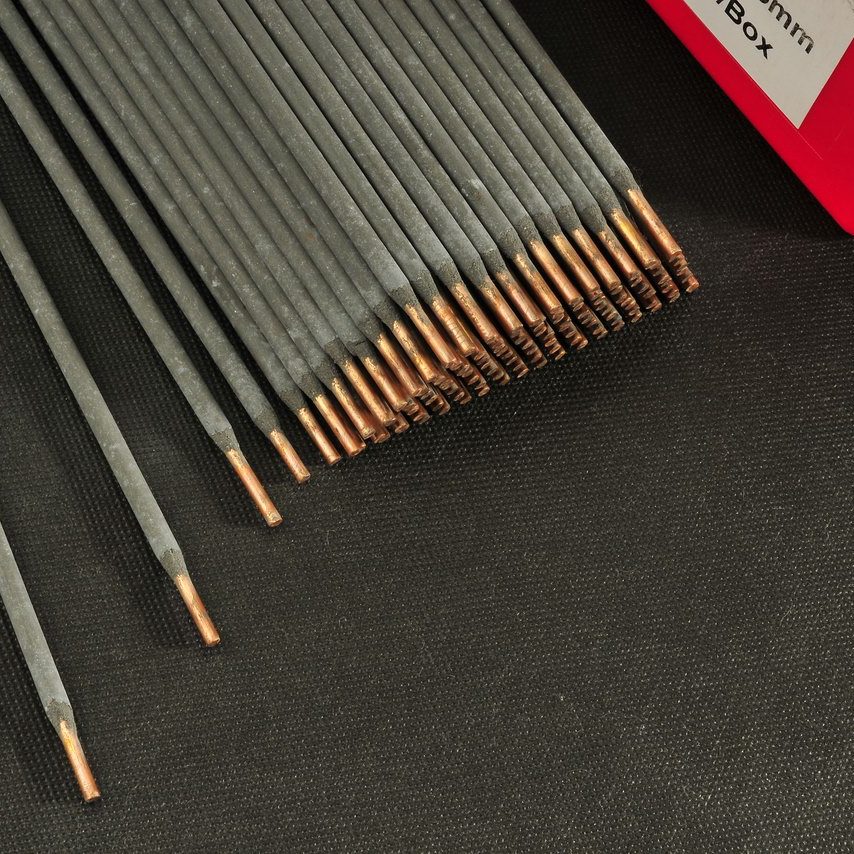

| Make up: | ||

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||