| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu5211 |

|

| BS EN14640:2005 | Cu 5211 |

|

| GB Chemical Composition: | % | |

| Cu incl.ag | bal. | |

| Zn | max 0.10 | |

| Sn | 9.00-10.00 | |

| Mn | 0.10-0.50 | |

| Fe | max 0.10 | |

| Si | 0.10-0.50 | |

| P | max 0.10 | |

| Al | max 0.01 | |

| Pb | max 0.02 | |

| Total others | max 0.50 | |

| Physical properties of materials: | ||

| Density | Kg/m^3 | 8.7 |

| Melting range | ℃ | 887-1020 |

| Thermal conductivity | W/m.K | 47 |

| Electrical conductivity | S.m/mm^2 | 5-6 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 18.0 |

| Standard values of the weld metal: | ||

| Elongation | % | 14 |

| Tensile strength | N/mm^2 | 290 |

| Notched bar impact work | J | 24 |

| Brinell hardness | HB 2.5/62.5 | 115 |

| Applications: | ||

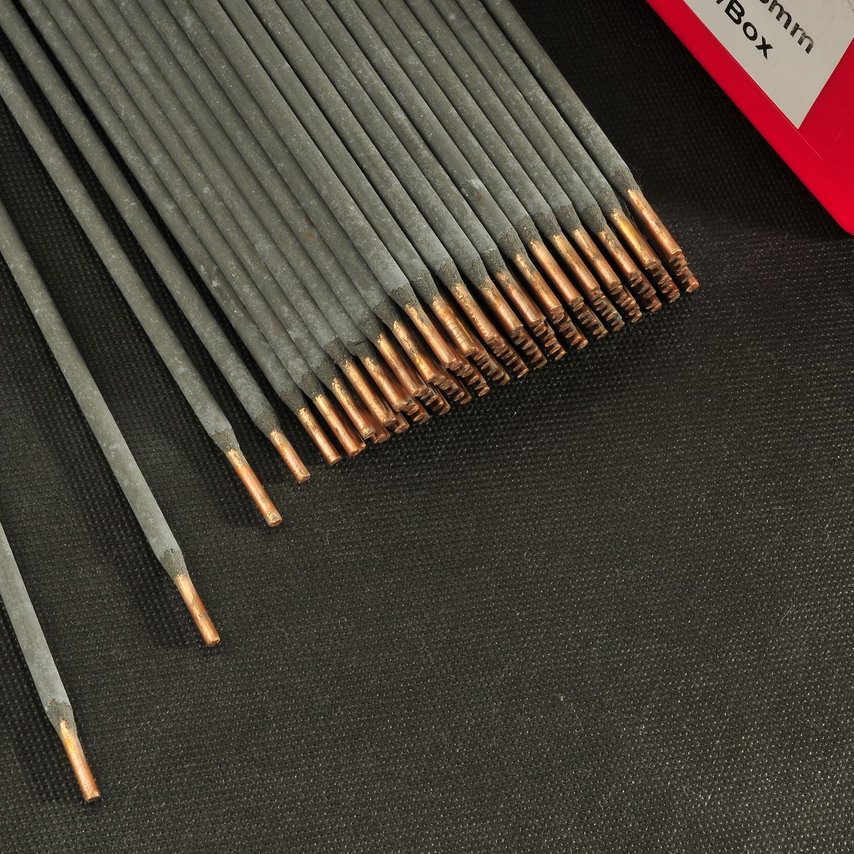

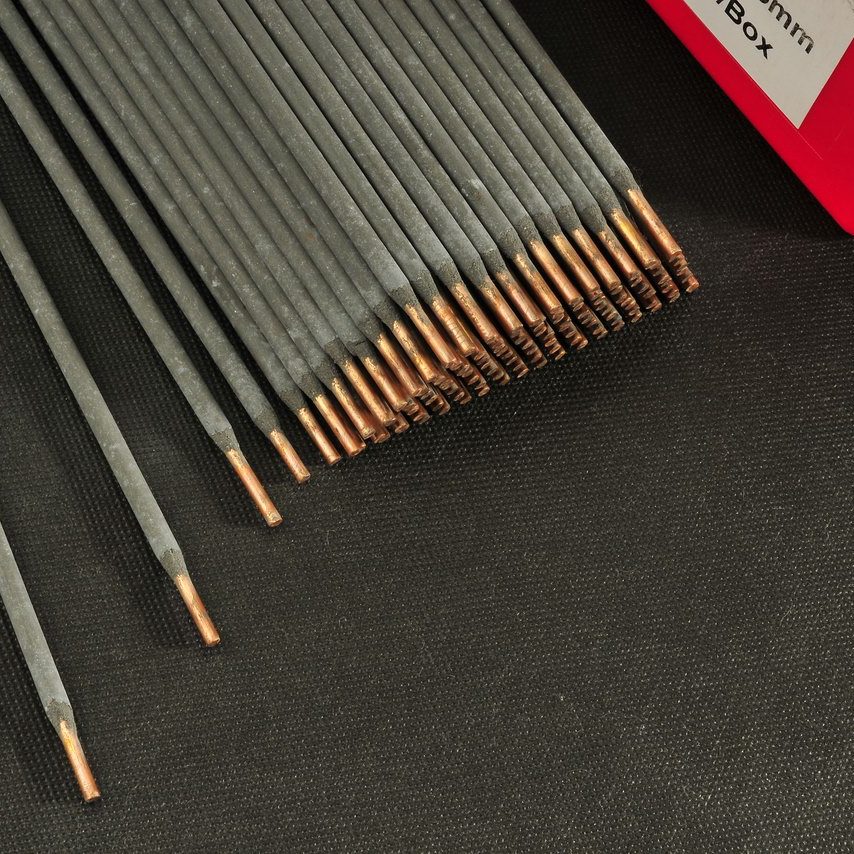

| Welding filler metal with good flowing properties.Low tendency to porosity and spatter.Appropriate for welding of copper materials,like copper,tin bronzes,especially suitable for joining of copper zinc alloys and steels.Particularly suitable for repair welding of bronze statues.For multilayer welding on steels,pulsed arc welding is recommended.For large work pieces preheating is recommended. | ||

| Make up: | ||

| Diameter:0.64 - 0.80 - 1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D100,D200,D300,D760,K300,KS300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||