| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu1897 |

|

| BS EN ISO24373:2009 | CuAg1 |

|

| DIN 1733 | SG-CuAg | |

| BS Chemical Composition: | % | |

| Cu incl.ag | min 99.5 | |

| Mn | 0.20 | |

| Fe | 0.05 | |

| Si | 0.10 | |

| Ni incl.Co | 0.30 | |

| P | 0.01-0.05 | |

| Al | 0.01 | |

| Pb | 0.01 | |

| As | 0.05 | |

| Total others | Ag:0.8-1.2 | |

| Physical properties of materials: | ||

| Density | Kg/m^3 | 8.9 |

| Melting range | ℃ | 1070-1080 |

| Thermal conductivity | W/m.K | 220-300 |

| Electrical conductivity | S.m/mm^2 | 44-46 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 17.6 |

| Standard values of the weld metal: | ||

| Elongation | % | 30 |

| Tensile strength | N/mm^2 | 200 |

| Notched bar impact work | J | 75 |

| Brinell hardness | HB 2.5/62.5 | 60 |

| Applications: | ||

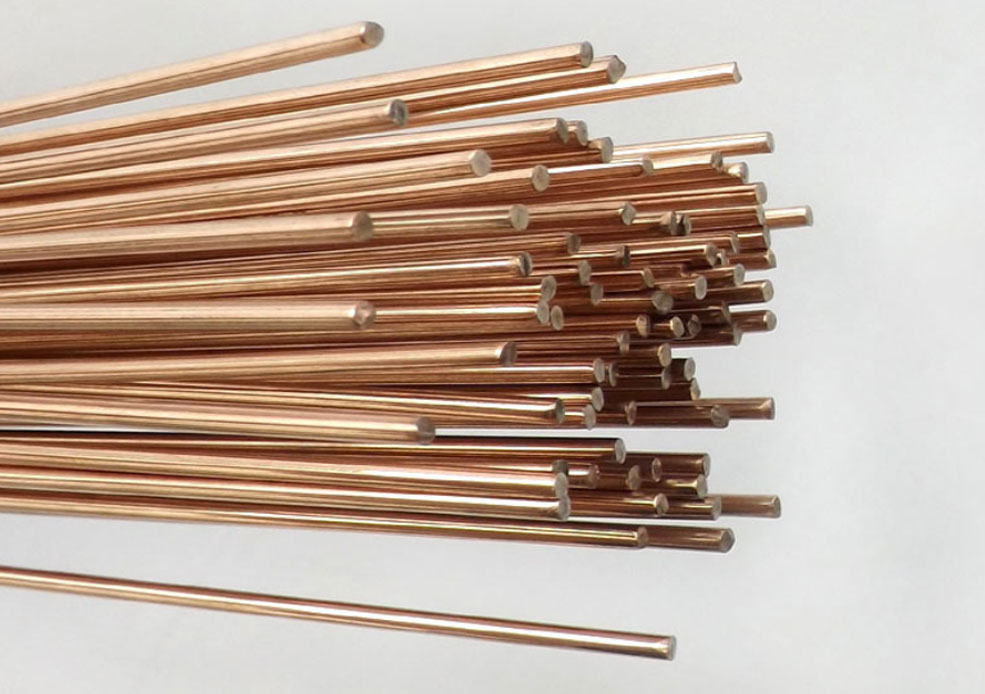

| Copper alloy for excellent welding process especially in guided postions.Viscous weld pool and free of pores.For large work pieces preheating is recommended. | ||

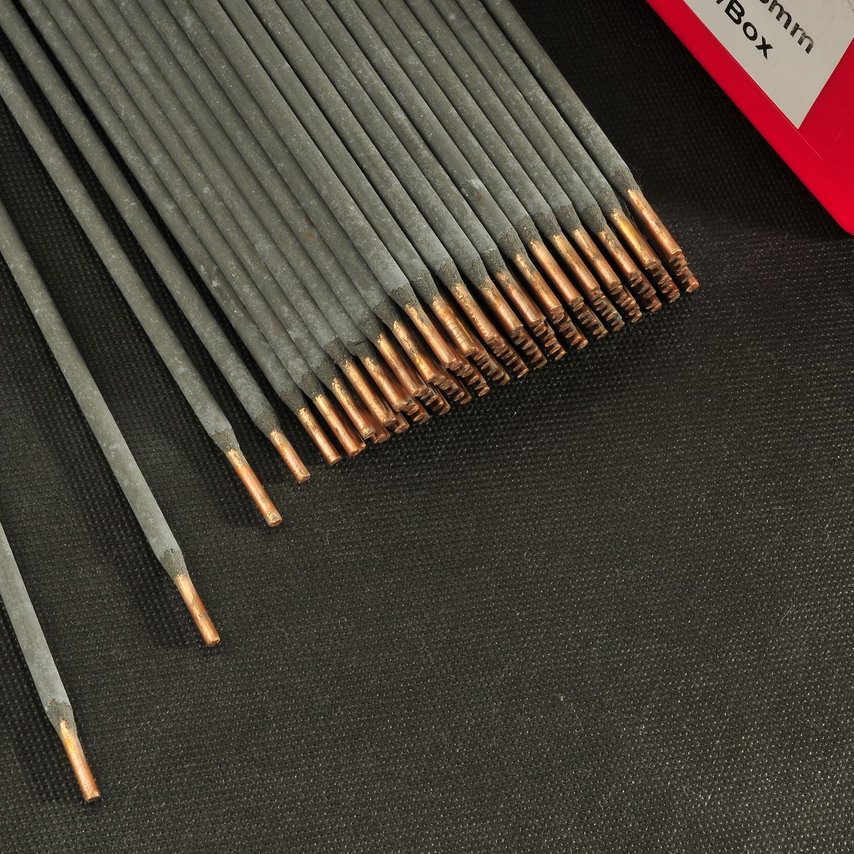

| Make up: | ||

| Rods:1.60 - 9.6 mm x 914/1000 mm | ||

| Further make ups on request. |

||