| Standardization: | Numberical Symbol: | |

| GB/T9460-2008 | SCu7061 |

|

| BS EN ISO24373:2009 | CuNi10 |

|

| DIN 1733 | SG-CuNi10Fe | |

| BS Chemical Composition: | % | |

| Cu incl.ag | bal. | |

| Mn | 0.50-1.50 | |

| Fe | 0.50-2.00 | |

| Si | max 0.20 | |

| Ni incl.Co | 9.00-11.00 | |

| P | max 0.02 | |

| Pb | max 0.02 | |

| Ti | 0.10-0.50 | |

| C | max 0.05 | |

| S | max 0.02 | |

| Total others | max 0.40 | |

| Physical properties of materials: | ||

| Density | Kg/m^3 | 8.9 |

| Melting range | ℃ | 1100-1145 |

| Thermal conductivity | W/m.K | 30 |

| Electrical conductivity | S.m/mm^2 | 2.8-3.2 |

| Coefficient of thermal expansion | 10^-6/K(20-300℃) | 17.0 |

| Standard values of the weld metal: | ||

| Elongation | % | 34 |

| Tensile strength | N/mm^2 | 300 |

| Notched bar impact work | J | 190 |

| Brinell hardness | HB 2.5/62.5 | 80 |

| Applications: | ||

| Used for welding of wrought to themselves or to each other.These filler metals also are used for welding the clad side of copper nickel clad steel.Preheating gernerally is not necessary.Welding is done in all positions.The arc should be kept as short as possible to assure adequate shielding gas coverage and thus minimize porosity.It may be used for surfacing applications where high resistance to corrosion,erosion is required. | ||

| Make up: | ||

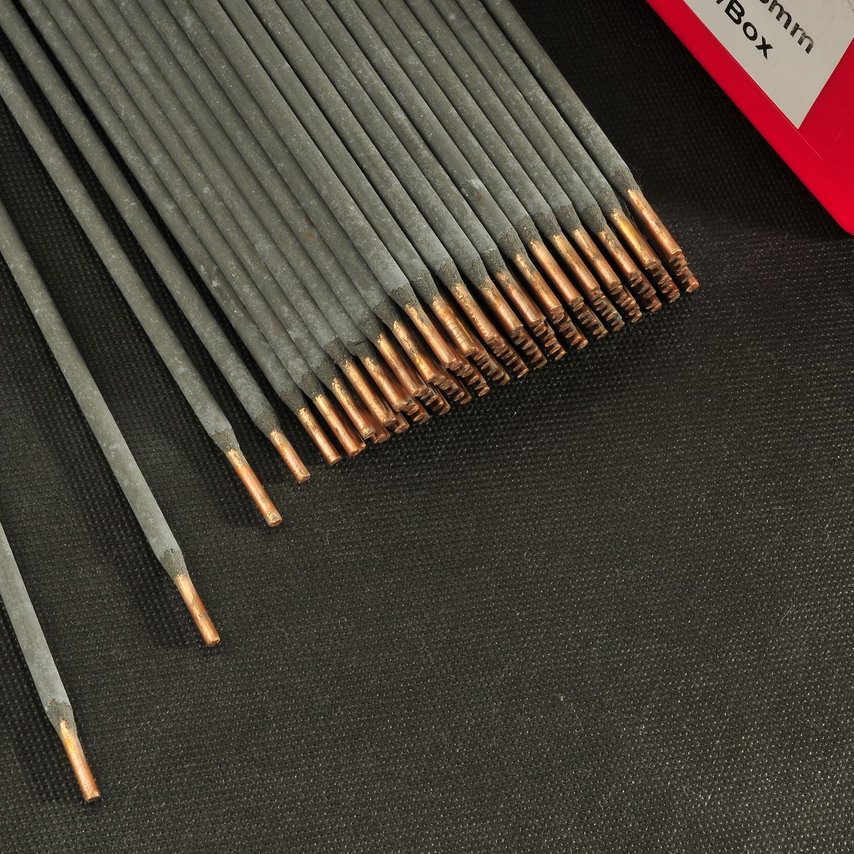

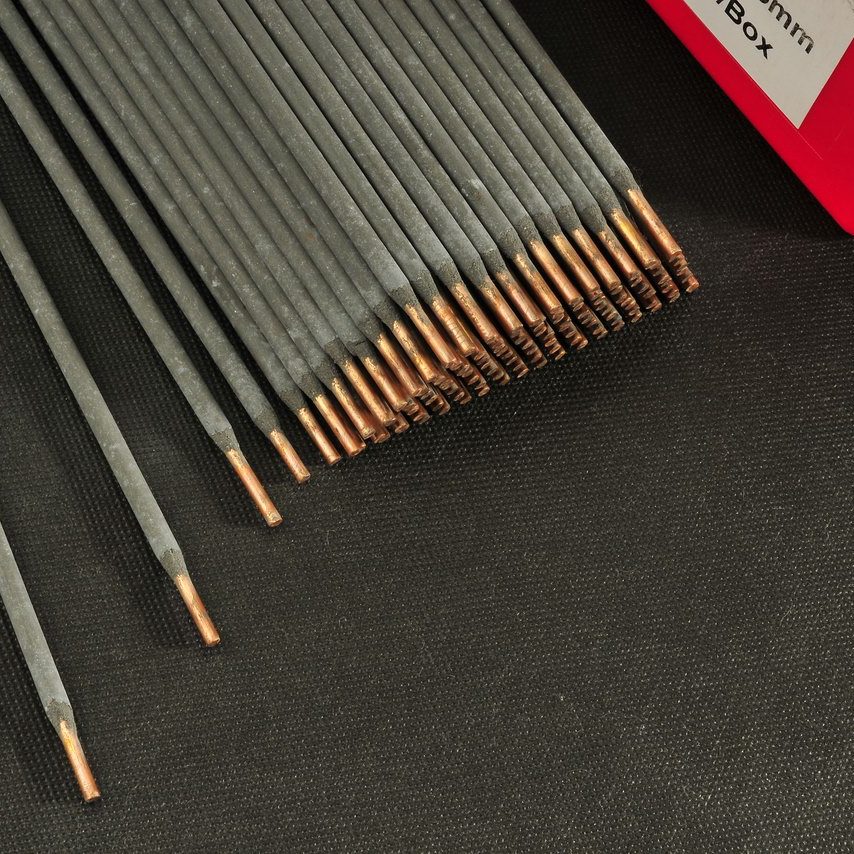

| Diameter:1.00 - 1.20 - 1.60 -2.40 |

||

| Spools:D300 |

||

| Rods:1.60 - 9.6 mm x 914/1000 mm |

||

| Further make ups on request. |

||